Use case 5 presents a great example of how human workers and robots will collaborate efficiently and support one another in future factories. The assembly of a kitchen hood at Silverline entails multiple steps that require distinct movements and skills, which are currently all performed by workers. Effective human-robot collaboration will lessen the physical burden on the worker, reduce errors, and increase efficiency of the process and thus production capacity.

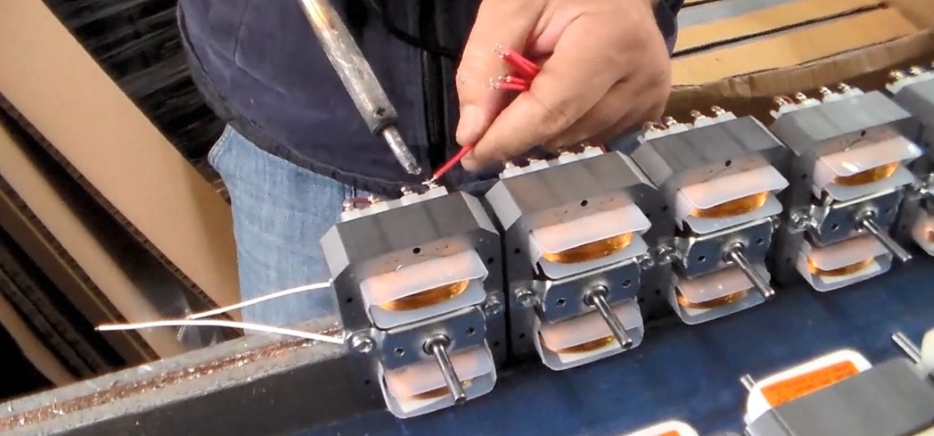

Cables need to be identified by colour or dimension to ensure correct and safe connections, and various other components need to be identified, moved, and placed with precision. As these actions are highly repetitive, and some components need to be moved around, the work is physically and mentally tiring, which increases the risk of mistakes. Effective human-robot collaboration will reduce the worker’s risk of injury and accelerate production.

Different components need to be identified by their shape and colour, checked for surface defects, and then moved into position precisely and efficiently. This is especially challenging when the components are compliant, such as cables, but precise placement is paramount for effective assembly. In addition, parts of various sizes—from small cables over propellers to large plastic body parts—need to be manipulated securely and without risking any damage. At all stages, the robot will collaborate with the human operator, so safety and predictability need to be ensured.