Use Case 1 – Food packaging

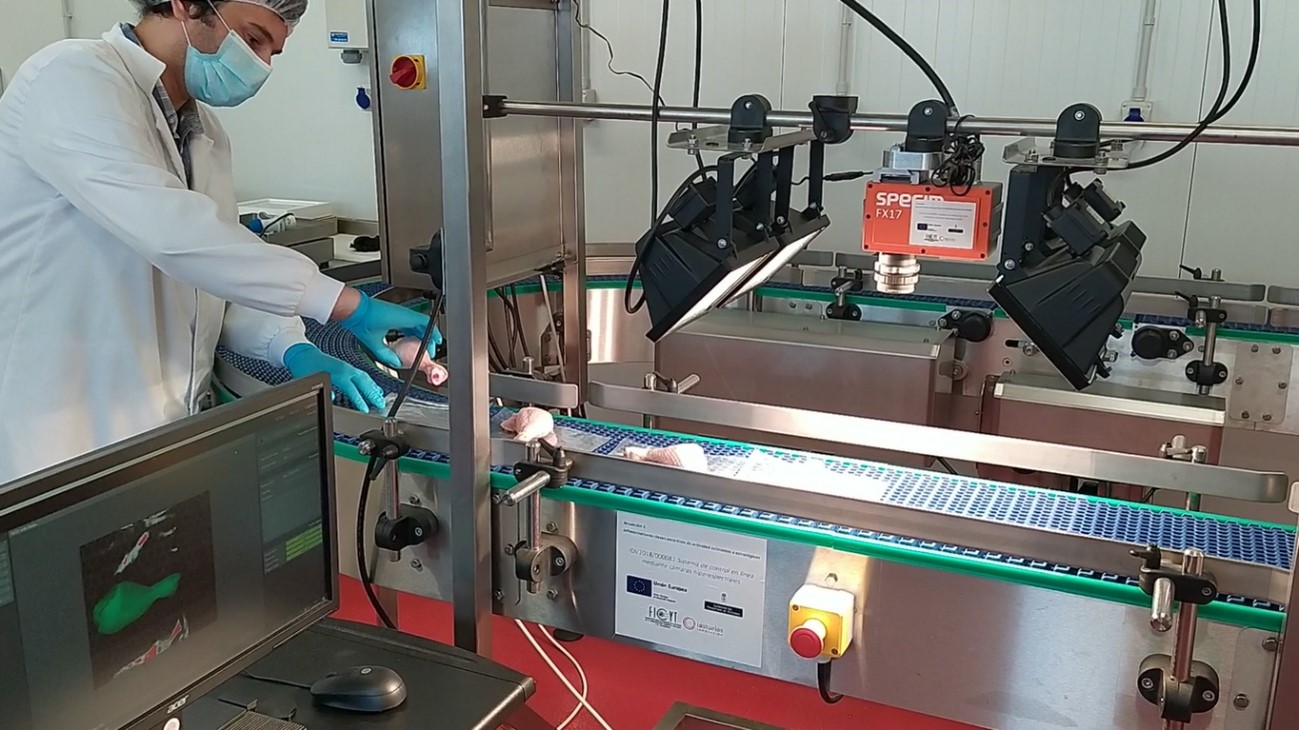

ASINCAR aims to semi-automate the process of food packing – in particular the one regarding chicken breasts and drumsticks. Besides handling the slippery meat in varying sizes, the robotic system will also analyse the shelf life of the product through real-time hyperspectral imaging. This way, different pieces will be classified by the robot according to their shelf life and the meat can be objectively analysed with respect to microbial contamination, leading to increased food safety and a reduction of food waste.

Direct human contact with food items raises the risk of food contamination, a safety issue introduced by the worker. In addition, the environmental conditions in the packaging room are challenging for the worker (low temperature and high humidity), and the required movements are repetitive and not ergonomic—a considerable safety issue to the worker. Regarding the determination of the shelf life, human workers perform this exceedingly quickly, relying on purely subjective criteria. This can negatively affect the quality of the product on one hand as well as the amount of unnecessary food waste on the other hand. Human-robot collaboration in these steps could alleviate the risks for the worker as well as the product.

Meat is a natural product that comes in different sizes, and it is soft, deformable and slippery, which makes dexterous handling particularly challenging. The food item needs to be grasped securely—without risking damaging it—and placed into the appropriate tray, depending on the estimated shelf life. In addition to the required dexterity, the manipulator needs to have a smooth surface that is easy to clean and disinfect to ensure the safety of the product.