Use Case 1 – Food packaging

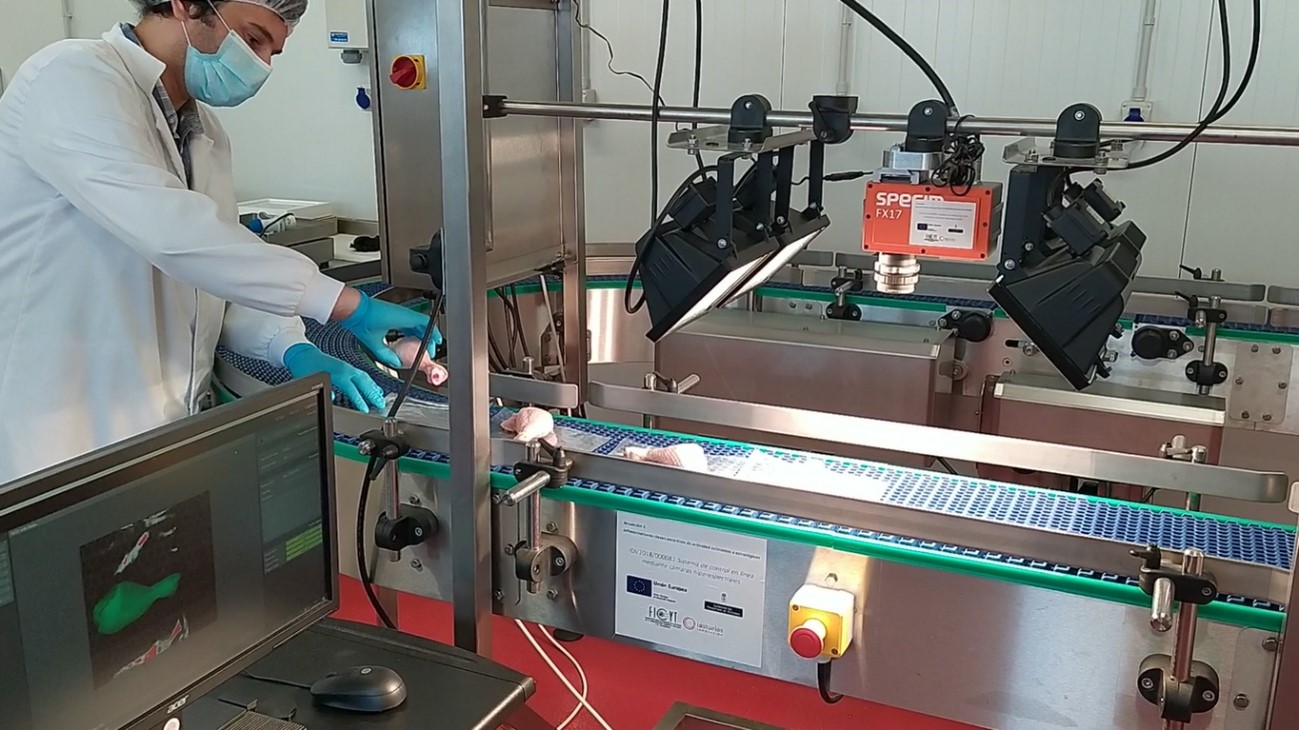

ASINCAR aims to semi-automate the process of food packing – in particular the one regarding chicken breasts and drumsticks. Besides handling the slippery meat in varying sizes, the robotic system will also analyse the shelf life of the product through real-time hyperspectral imaging. This way, different pieces will be classified by the robot according to their shelf life and the meat can be objectively analysed with respect to microbial contamination, leading to increased food safety and a reduction of food waste.

Direct human contact with food items raises the risk of food contamination, a safety issue introduced by the worker. In addition, the environmental conditions in the packaging room are challenging for the worker (low temperature and high humidity), and the required movements are repetitive and not ergonomic—a considerable safety issue to the worker. Regarding the determination of the shelf life, human workers perform this exceedingly quickly, relying on purely subjective criteria. This can negatively affect the quality of the product on one hand as well as the amount of unnecessary food waste on the other hand. Human-robot collaboration in these steps could alleviate the risks for the worker as well as the product.

Meat is a natural product that comes in different sizes, and it is soft, deformable and slippery, which makes dexterous handling particularly challenging. The food item needs to be grasped securely—without risking damaging it—and placed into the appropriate tray, depending on the estimated shelf life. In addition to the required dexterity, the manipulator needs to have a smooth surface that is easy to clean and disinfect to ensure the safety of the product.

Use Case 1 (Food Packing), during the last three and a half years, has focused on the development of prototypes of dexterous, autonomous, agile and low-cost robots capable of manipulating, assembling or processing different soft and flexible products/materials in the production environment. To achieve this objective, the APRIL platform integrates multiple innovative technologies: such as a novel robotic hand, which has product handling capabilities (grip, subtlety, non-invasive, etc.) not available on the market; or multi-sensor feedback that enables interaction of the robot with the environment, manipulation of the robot, motion planning, ergonomic work of the operator, as well as safe task performance.

The complete platform related to the food use case (chicken-based food samples) was available in the ASINCAR pilot plant (Pol. De la Barreda, C/ Solellero, 5) in Noreña, Asturias (Northwest Spain) from September 27th to October 11th 2023. To demonstrate its performance, a DEMO WORKSHOP was celebrated on 10th October 2023 with the title: Meat and food packaging processes through a robotic solution: demonstration of the APRIL platform

Main workshop objectives were:

- To show through a demonstrative approach the different functionalities and technologies integrated into the APRIL robotics platform, including:

- Intelligent classification of chicken pieces based on their shelf life.

- Automated handling and packaging of chicken parts according the shelf life.

- Detection and identification of chicken pieces on the conveyor belt.

- Task planning.

- To present the technological advances and main results achieved within the project.

- Interaction and networking with relevant technological actors at European level

Working on Use Case 1 with the goal of promoting participant engagement, ASINCAR has primarily used the survey tool. In this regard, it has achieved the following results.

End-user surveys: 17:

- 7 from ASINCAR and;

- 10 external companies.