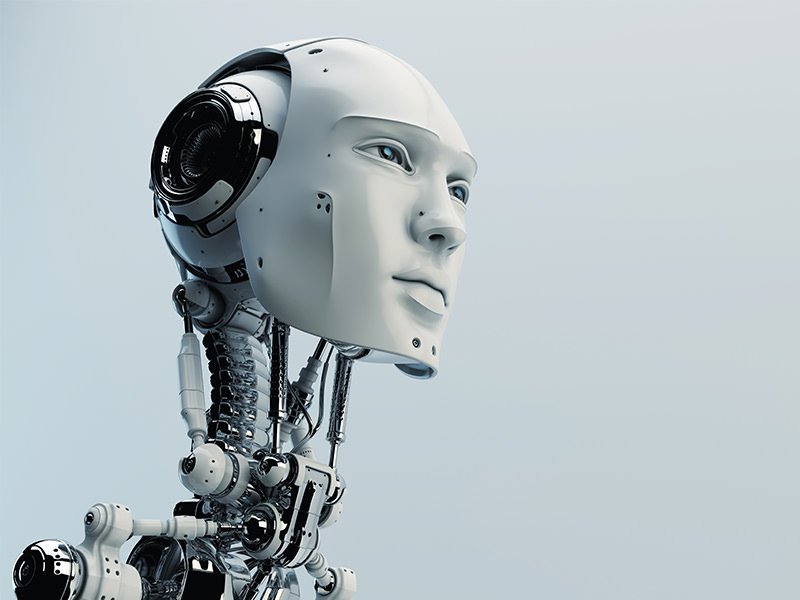

A new generation of robots to innovate the ways to handle flexible and deformable materials for manufacturing products in European enterprises

Interdisciplinary consortium composed by 15 European partners coordinated by the Universidad Politécnica de Madrid

What once seemed the far future for many large and small businesses is now well-established solution. Today robotics is a technology designed to innovate the ways to produce and the manufacturing enterprises. In this scenario, the 15 European partners which collaborate at the new research project APRIL aim at prototyping low cost and agile market oriented multipurpose, and easy to repurpose, autonomous dexterous robots; which will manipulate, assemble or process different soft and flexible products/materials in a production line environment. Through an innovative approach, the project team will develop robots with features that can adapt to different production scenarios (manufacturing, assembly, food-service industries).

APRIL project will run for a period of 40 months with a total budget of almost EUR 8 million provided by the European Union’s Horizon 2020 – Factories of the Future (FoF).

The Project

Robotics is enabling a transition to a flexible, digitalized and demand-driven manufacturing sector where organizations are making the necessary adaptations in terms of manufacturing excellence and flexibility, including skills development, to capitalize on the increasing demand for more customized and higher-quality products. APRIL will enable new ways of automatization (semi- or fully-automated tasks) in manufacturing lines that produce, assemble or handle different types of flexible or deformable materials. To reach this objective, APRIL will develop and build demonstrative robotic prototypes optimized for soft and deformable materials processing in the manufacturing environments.

The new generation of robots will be: safe to deploy around people with no guarding; more skilful and competent at handling different types of soft products while controlling their level of deformation; able to supervise all additional information of the product (colour, healthy state of food, etc.) during the handling; more adaptable and able to learn in new interactive environments; as well as more capable of being moved from line to line, and job to job, as needed.

“In APRIL we want to help changing the world by empowering the people working in the manufacturing industry with cobots, enabling a broad range of users, particularly SMEs, to lower the barriers towards automation. In APRIL, we have a great multidisciplinary team and the resources to innovate in technologies for the handling of the soft and flexible materials in the production line; while disrupting novel ways for safe human-robot interaction in areas such as textile, paper handling, food processing, or those where it had not been practical to automate before.”

María Teresa ARREDONDO and Xenia BELTRAN (UPM), Project Coordinators

APRIL`s demonstration pilots will approach the challenge of providing robots that can come closer to matching people’s fine motor skills in manipulating materials and small parts, dealing with flexible and soft materials (such as cloth), transparencies (such as packaging materials), specular materials (such as chrome-plated objects) and tiny objects (such fixing as cables).

APRIL project is coordinated by the Universidad Politécnica de Madrid. The consortium is composed by 15 European partners from 8 EU countries.

The project officially launched its activities with a first meeting on 28 April 2020.